Morales wasn’t satisfied with a century of tradition in his field. For one thing, it was a painstaking, 14-step process that had to be done one sample at a time using environmentally unfriendly solutions. For another, the science of pathology was falling behind. Because of the damaging chemicals used, pathologists couldn’t study tissue with medical innovations like RNA molecular analysis.

Technicians needed 12 hours to process the samples and embed them in paraffin, which had to be completed before a pathologist could examine the samples and write a report. Patients couldn’t get results for at least one day after surgery—usually two.

![]() n 1997 Morales began refining a new

technique with some longtime colleagues, Ervin Essenfeld, M.D., and his

son Harold Essenfeld, M.D., pathologists

in Caracas, Venezuela. They found a more efficient way to use an existing

tool to expedite the processing of tissue.

n 1997 Morales began refining a new

technique with some longtime colleagues, Ervin Essenfeld, M.D., and his

son Harold Essenfeld, M.D., pathologists

in Caracas, Venezuela. They found a more efficient way to use an existing

tool to expedite the processing of tissue.

The tool was a microwave.

|

||

|

||

That little convenience, found in so many offices and homes, cooks food by agitating water molecules, making them gyrate against each other so vigorously that the friction creates heat. If the water gets hot enough, it evaporates. Although microwave technology had been used in histopathology labs for more than 25 years, it was modified kitchen microwave technology. RTP uses specially designed microwaves that allow for uniform heating in an automated system that does not dry out or damage the tissue.

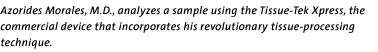

Now, after seven years of development, documentation, and daily operation at UM, the fully automated RTP system is for sale for the first time to hospitals and labs around the United States.

“Rapid tissue processing is both continuous and rapid,” says Morales, who holds numerous patents on this process, alone and jointly with the Essenfelds. UM also holds multiple U.S. and foreign patents on this method of microwave processing of pathology tissue, the RTP instrument, and the reagent chemicals. The process has been licensed to Sakura Finetek USA Inc., which is manufacturing the instrument.

![]() rom the perspective of a technician,

the RTP is actually much, much better,” says

Carmen Duboue, a histopathology technologist in the Department

of Pathology.

rom the perspective of a technician,

the RTP is actually much, much better,” says

Carmen Duboue, a histopathology technologist in the Department

of Pathology.

![]() Rapid tissue processing uses fewer

reagent chemicals and far less toxic reagents than the conventional process.

For

example,

RTP

doesn’t

use formalin, a known toxin and environmental hazard used

in pathology since 1893. Formalin also destroys RNA in

tissue, while the new reagents

do not, making molecular assays feasible in wax-embedded

tissue for the first time.

Rapid tissue processing uses fewer

reagent chemicals and far less toxic reagents than the conventional process.

For

example,

RTP

doesn’t

use formalin, a known toxin and environmental hazard used

in pathology since 1893. Formalin also destroys RNA in

tissue, while the new reagents

do not, making molecular assays feasible in wax-embedded

tissue for the first time.

A one-year blind study comparing conventional and rapid tissue processing showed comparable quality. The findings were published in April in the American Journal of Clinical Pathology.

It is projected that royalty income from the device will propel the University into the top 14 percent of universities involved in technology transfer.

“We tell breast biopsy patients they can wait in the lobby for results,” says Duboue. Other patients may get their results while they’re still in the recovery room. At UM, two-thirds of tissue pathology reports are now available on the same day as the biopsy.

There are more innovations on the

way, including the introduction of virtual microscopy studies of

clinical

samples. “This will make it much easier

to share and collaborate on tissue pathology,” says

Morales.

Kelly Kaufhold is a senior media relations officer and writer in the Office of Communications at the School of Medicine. Photography by John Zillioux.